ANSI & ISO End Suction Pumps

We supply both ISO2858 & ANSI B73.1 Chemical Process Pumps, and Slurry (Solid Handling) Industrial Pump.

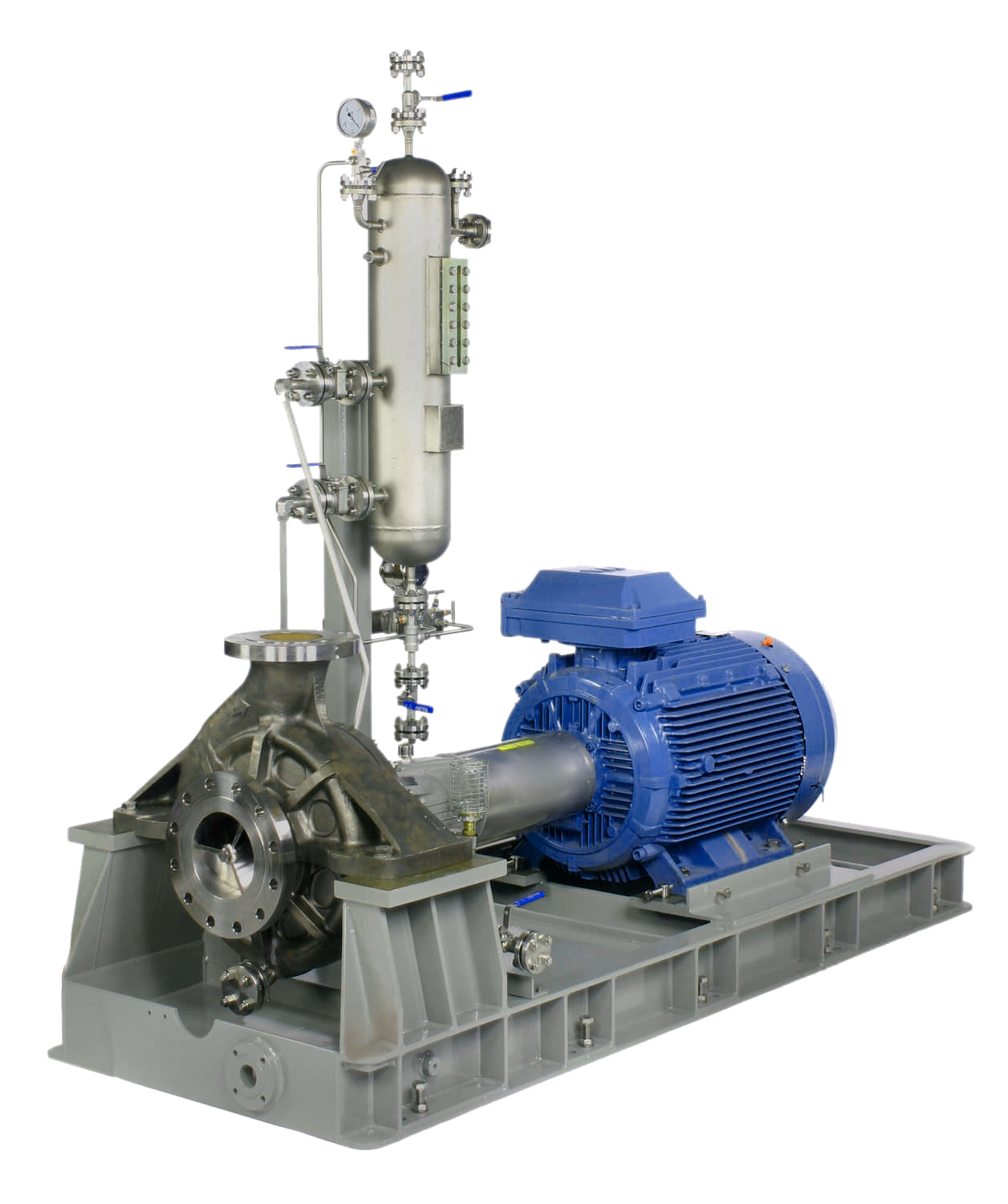

API 610 (OH2) Process Pump

Horizontal, radial split. single stage, overhung centrifugal pump with volute casing. Structure design has thought-out and mature consideration on suppot connection, bearing cooling, etc.

Sorts of available auxiliary and monitoring instruments obtain high safety and reliability. Top leading high efficiency and energy saving products provides better service life, simple maintenance, strong universality, less spares, excellent hydraulic performance, good cavitation resistance, etc.

Capacity : 2-2,600ml/h

Head: -300m

Temperature: -80~+450'C

Pressure: ~5 Mpa

API 610 (BB2) RADIAL SPLIT Heavy Duty Process Pump

Horizontal, radially split. single stage, double suction. between- bearings centrifugal pump which is designed for heavy duty unit, with simple and reliable structure, stable operation, convenient maintenance, long service life.

Impeller. Single or double suction, without asial force. Double suction impeller could extend the bearing life when operating in high pressure and have good cavitation-resistance.

Casing: Axial force is balanced by double volute type structure. Temperature deformation is balanced by centreline-mounted.

Casing cover: Rigid design, high pressure-resistance

Bearing: Self-lubricating antifriction bearing, sliding bearingor forced lubricating bearing are available by different rate power, which could guarantee the safety and reliable operation.

Capacity: 5-5,000m3/h

Head: 350m

Temperature : -80-+450'C

Pressure: 5Mpa - 10Mpa

API 610 (BB3) VOULTE CASING, AXIALLY SPLIT MULTISTAGE PUMP

Horizontal, single-casing, axially split, centreline-mounted between-bearings centrifugal pump. The radially force is self balanced by volute type flow channel which is symmetrically arranged along the center line. the axial force is self-balanced by back to back arranged impellers, the complex balance devices aren't needed, especially good for transfer the liquid which contains particles.

The suction and discharge are cast with casing, which the rotor pans could be easily maintained without dismounting the suction and discharge pipelines, and reduce the shutdown

period.

Capacity : 10-l,600ml/h

Head : -l,600m

Temperature: -80-+200'C

Pressure : -25Mpa

API 610 (VS1 & VS6) VERTICAL MULTISTAGE PUMP

Double-casing multi-stage vertically suspended pumps with bowl type diffuser. The top antifriction bearing is lubricated by oil. The bottom sliding bearing is multi-point supported.

The first-stage impeller can be single- or double-suction, it al.so can be lower arranged. The axial force is efficient balanced by balance drum which can not be impacted by axial position.

Structure design has thought-out and mature consideration on support, connection, bearing cooling, etc. Sorts of available auxiliary and monitoring instruments make it high safety and reliability.

Capacity : -2.soom3/h

Head : -soom

Temperature: ·120-+250'C

Pressure· -10Mpa