Toughmet 3 Rod Couplings

- Eliminate frequent workovers, lower production costs and improve margin and cash flow

- Designed to resist tubing-coupling wear. Increase tubing life.

- Low Friction / Non Galling.

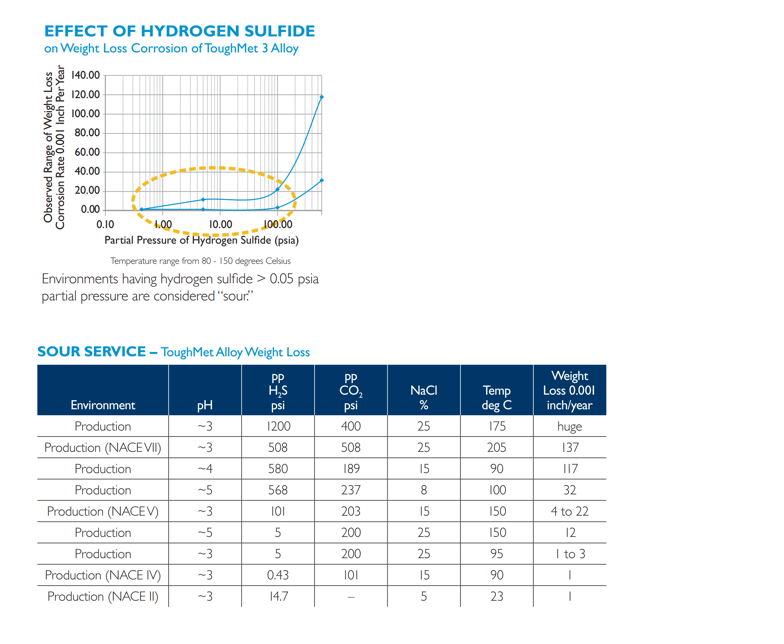

- Corrosion Resistant.

- High fatique strength.

- Increase pump efficiencies.

Download Brochure

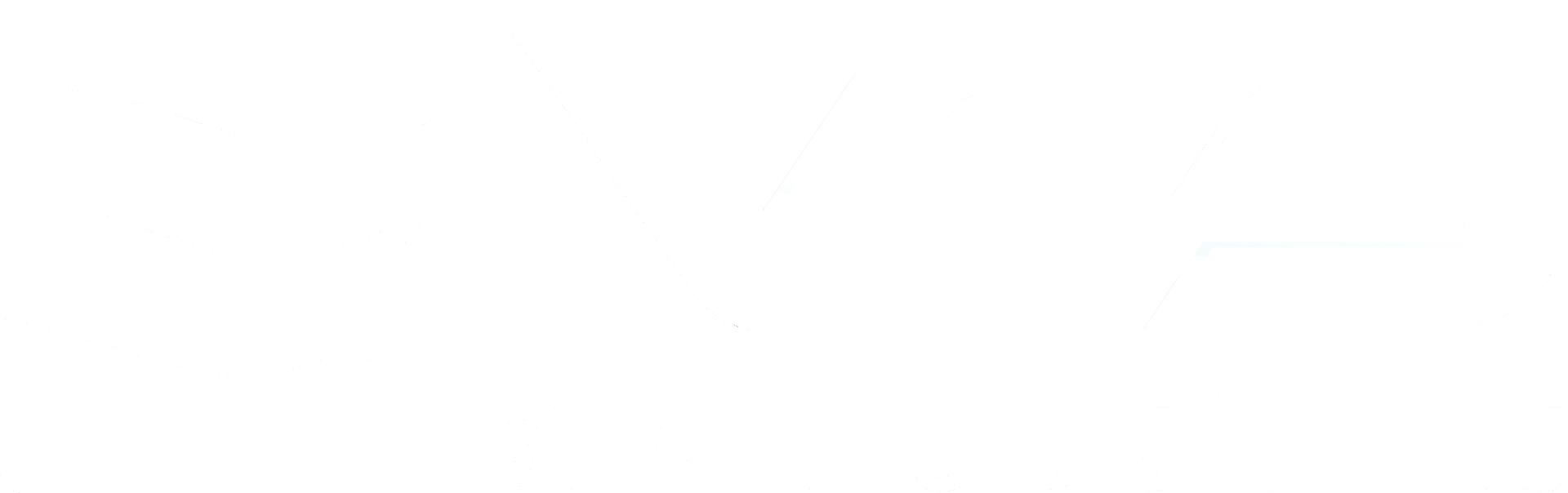

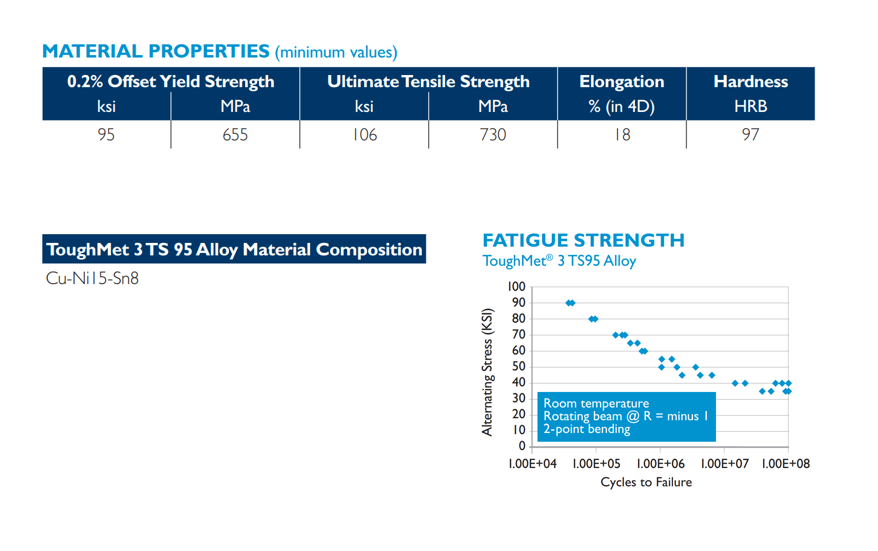

ToughMet copper-nickel-tin alloys have been successfully used in the oil and gas industry for decades. The newest ToughMet temper—ToughMet 3 TS 95 material—was specifcally engineered for ToughMet sucker rod couplings, which eliminate well failures caused by coupling-on-tubing wear.

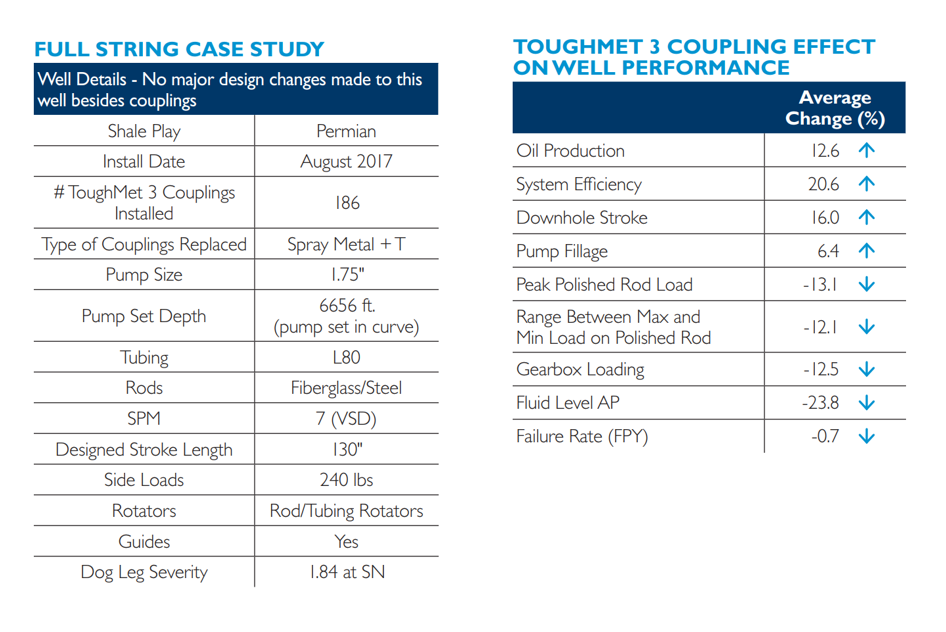

In addition, wells using 150 or more ToughMet couplings can increase production by nearly 13% due to lower friction, improved plunger travel and increased well effciency. This low friction property is ideal for deviated wells that experience high friction issues such as rod hang-ups, buckling and compression.

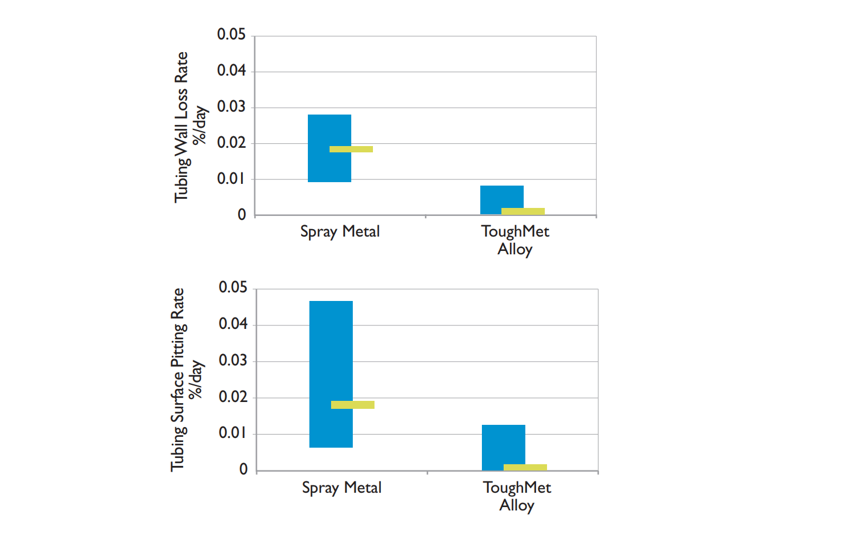

Toghmet 3 couplings are proven to increase mean time between failures (MTBF) of wells that experience high levels of tubing wear. Results show that the couplings increases tubing life by 3x compared to spray metal couplings and 2x compared to T couplings.

All ToughMet 3 couplings are manufactured to API 11B sucker rod coupling dimensions.

Advantages of the Hydraulic Tubing Anchor

Specifications

Sucker Rod Couplings

| Coupling Sizes | OD - Full Size | OD - Slim Hole |

|---|---|---|

| 5/8" | 1.50" | 1.25" |

| 3/4" | 1.625" | 1.50" |

| 7/8" | 1.812" | 1.625" |

| 1" | 2.187" | 2.000" |

| 1-1/8" | 2.375" | N/A |

Cross-over Couplings

| Coupling Sizes | OD - Full Size | OD - Slim Hole |

|---|---|---|

| 7/8" x 3/4" | 1.812" | 1.625" |

| 1" x 3/4" | 2.187" | 2.000" |

| 1" x 7/8" | 2.187" | 2.000" |

| 5/8" x 3/4" | 1.625" | 1.500" |

Polished Rod Couplings

| Coupling Sizes | OD - Full Size | OD - Slim Hole |

|---|---|---|

| 3/4" | 1.625" | 1.50" |

| 7/8" | 1.812" | 1.625" |

| 1" | 2.187" | 2.000" |

| 1-1/8" | 2.375" | N/A |