Hydraulic Tubing Anchors

- Simple to install, simple to extract

- Sets and unsets automatically

- Strong holding power, maximizes pump efficiency

- No surface manipulation or pretension needed

- Can only move downwards, keep tubing in constant tension

- Large bypass for gas, solids, survey tools

Download Brochure

Black Gold Pump & Supply is proud to be the leading innovator of the Hydraulic Tubing Anchor. Years of research, development and improvements resulted in this revolutionary product being deployed worldwide, replacing conventional mechanical anchors with its many benefits and advantages.

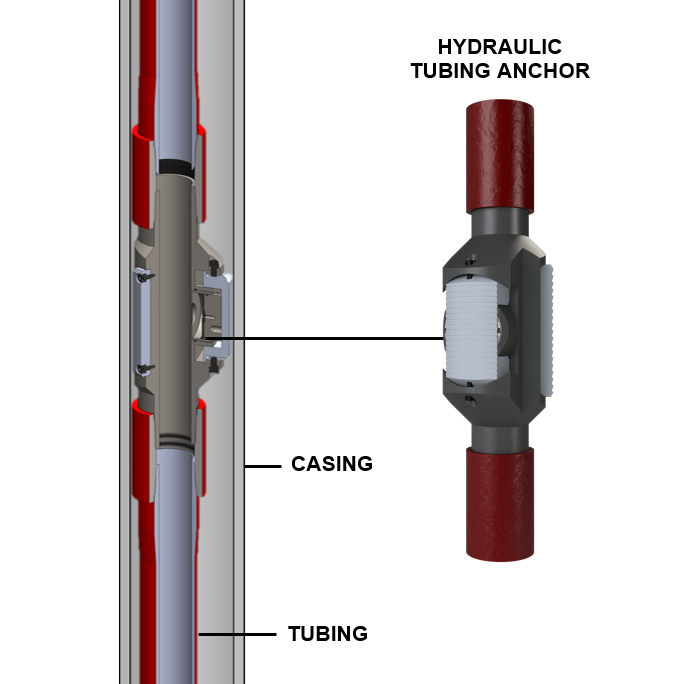

The hydraulic tubing anchor is a completely automatic tool that utilizes the weight of the fluid column in the tubing string to power the piston in the anchor. Load reversal from the pump is the force that moves the hydraulic tubing anchor into tension. When the differential pressure in the tubing string is greater than the pressure in the casing annulus, the anchor piston will be activated hydraulically and press the live slip against the casing.

Only 10 psi of differential pressure is needed to activate the piston. The anchor’s holding power is designed to resist upward movement against the normal forces encountered in the pumping operation, but will yield to forces beyond normal that would over stress the tubing string.

Fixed slips are designed to span recesses, and are built with a proprietary tooth angle, which allows the anchor to move down the hole into proper tension position, but restricts upward movement.

Because they are simple to install and extract, the ease of operation is a strong advantage of hydraulic tubing anchors. Unlike a mechanical anchor, there is no need for surface manipulation to set a hydraulic anchor.

The hydraulic anchor is activated when the insert or tubing pump is set and the pressure in the tubing string is greater than the pressure in the casing annulus. To retrieve the anchor,simply unseat the pump. The pressure will equalize and the anchor will no longer be in tension.

Advantages of the Hydraulic Tubing Anchor

Simple installation and extraction

The Hydraulic Anchor is simple to install and simple to extract. The anchor comes with pre-made-up tubing couplings and the installtion process is just like adding a pup joint section.

Extraction is also straighrforward, once the anchor is disangaged (unsets), simply pull tubing to extract the anchor.

Sets and unsets automatically

The Hydraulic Anchor set and unsets via hydraulic differential pressure between the casing and the tubing. Once the pump seats, producers can either fill the tubing with fluid or start pumping fluid into the tubing. A low 10psi differential is all that is needed to set the anchor.

To unset the anchor, simple unseat the pump or or have a hole in tubing (via tubing drain), or reverse circulate the well.

Unlike conventional mechanical anchor, there is no surface manipulation needed.

No surface manipulation or pretension

Unlike conventional mechanical anchor, there is no surface manipulation or pre-tensioning needed. The Hydraulic Anchor sets automatically via hydraulic differential pressure between the casing and tubing.

Producers typically save 45 minutes and up to a couple hours installing the Hydraulic Anchor instead of a conventional mechanical anchor.

Strong Holder Power

The Hydraulic Anchor has a strong holding power and is directly proportionate to the weight of the fluid column above the pump as the casing fluid level draws down. Which means the anchor holds stronger when its needed the most, resulting in higher pump efficiencies.

Keeps tubing in constant tension

Because the Hydraulic Anchor can only move downwards and not upwards, the anchor keeps the tubing in constant tension as the tubing elongates due to tubing fluid column's increasing weight as the well pumps down.

This constant tension ensures that the tubing will not experience buckling which cases rod/tubing wear.

Large bypass for gas, solids, survey tools

The Hydraulic Anchor has an average of 240% greater by-pass clearance compared to a mechanical anchor. This large by-pass has benefits for wells with high gas production, solids movements and cable/capillary tubing bundled on the side of the tubing.

The large by-pass will not allow gas slugs to form below and sand bridges build above the hydraulic anchor. Large by-pass also allow ample clearance for banding of downhole gauge wires and capillary tubing.

Specifications

| Casing Size Range (inch) | 4.5”, 5”, 5-1/2”, 7”, 7-5/8”, 8-5/8”, 9-5/8” |

|---|---|

| Tubing Size Range (inch) | 2.375, 2.785, 3.50 |

| Minimum Pressure To Set | 10 psi |

MENU

CONTACT US

Office, Pump Shop & Warehouse

Unit 4, 37-39 Devlan StreetMansfield 4122 QLD

Phone +61 7 3062 9475Fax +61 7 3252 7752

sales@vitalfluidsystems.com.au

STAY CONNECTED

Join our newsletter and find out more

Contact Us

We will get back to you as soon as possible

Please try again later