Specialty Rod Pumps

Specialty Rod Pumps

- For solutions above and beyond the capabilities of a standard API rod pump.

- Solutions to move more solids, gas, scale, paraffin

- Mitigating pump damages cause by fluid washing, corrosion, beat-out cages, failed ball & seats.

- Capabilities to push the limits of rod pump fluid production.

Black Gold Pump & Supply, Inc. has been engineering and developing specialty pumps over the last 3 decades as a response to the growing need in the oil & gas industry for solutions above and beyond the capabilities of a standard API rod pump.

Pumps are available in different lengths and material to address the different downhole challenges. Click here to contact us, and we can review your well.

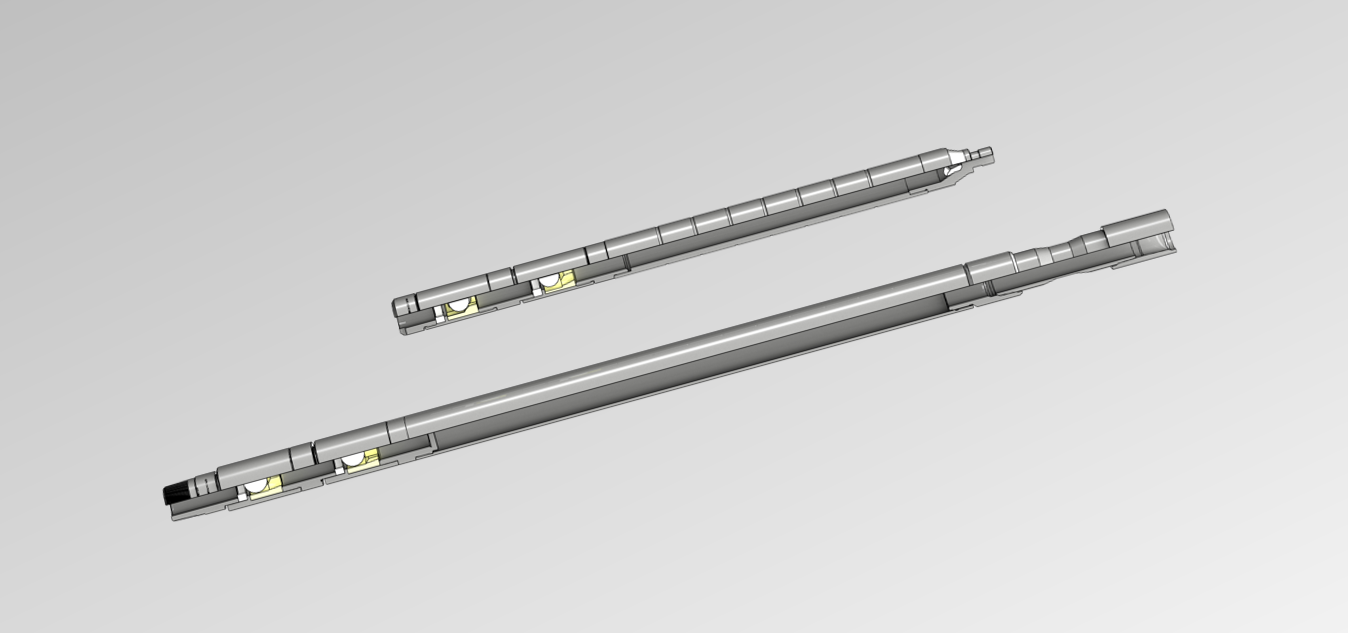

GAS BOOSTER PUMP

Black Gold Pump & Supply’s Gas Booster Pump is the most effective solution for gassy well application. The pump is designed to mitigate gas interference and gas locking by allowing gas to break out within the pump into a special vacuum compression chamber on every upstroke and gets moved out of the pump on every down stroke.

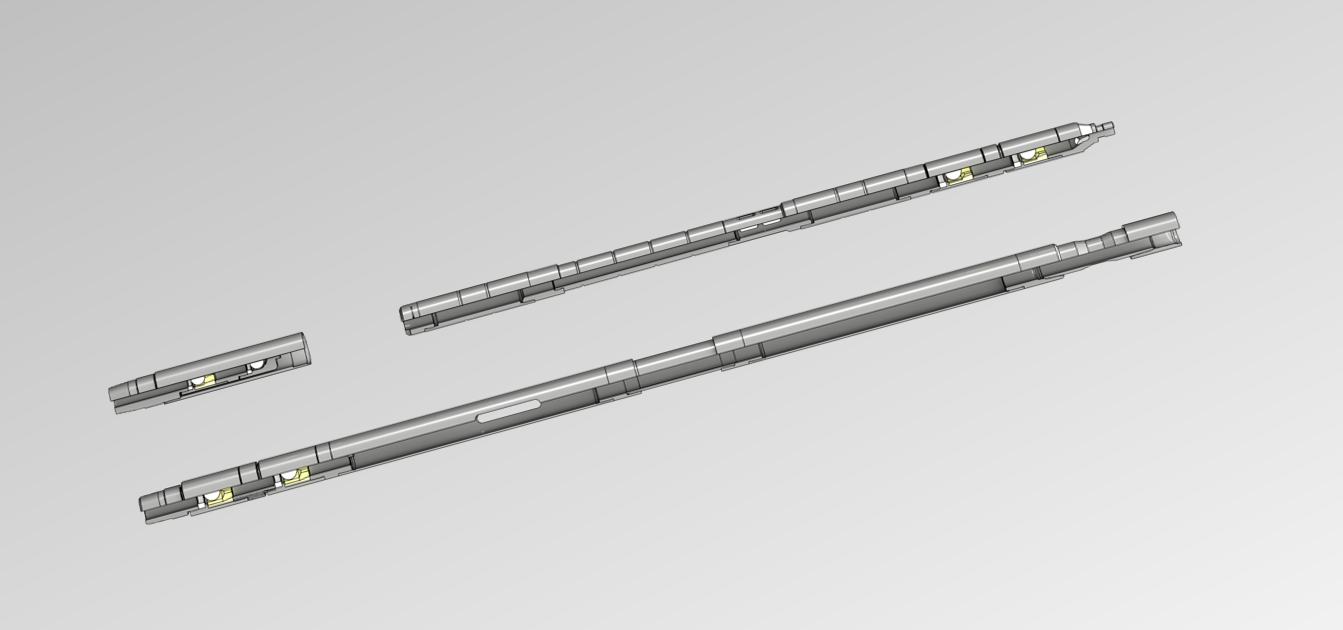

STROKE THROUGH PUMP

Black Gold Pump & Supply’s Stroke Trough Plunger Pump is designed for wells with sand, scale, and/or trash. Based off your well conditions and unit, a shorter barrel is used with long extensions and plunger. As the pump strokes, the plunger is always protruding out of the barrel. A sand seal is recommended below the valve rod guide.

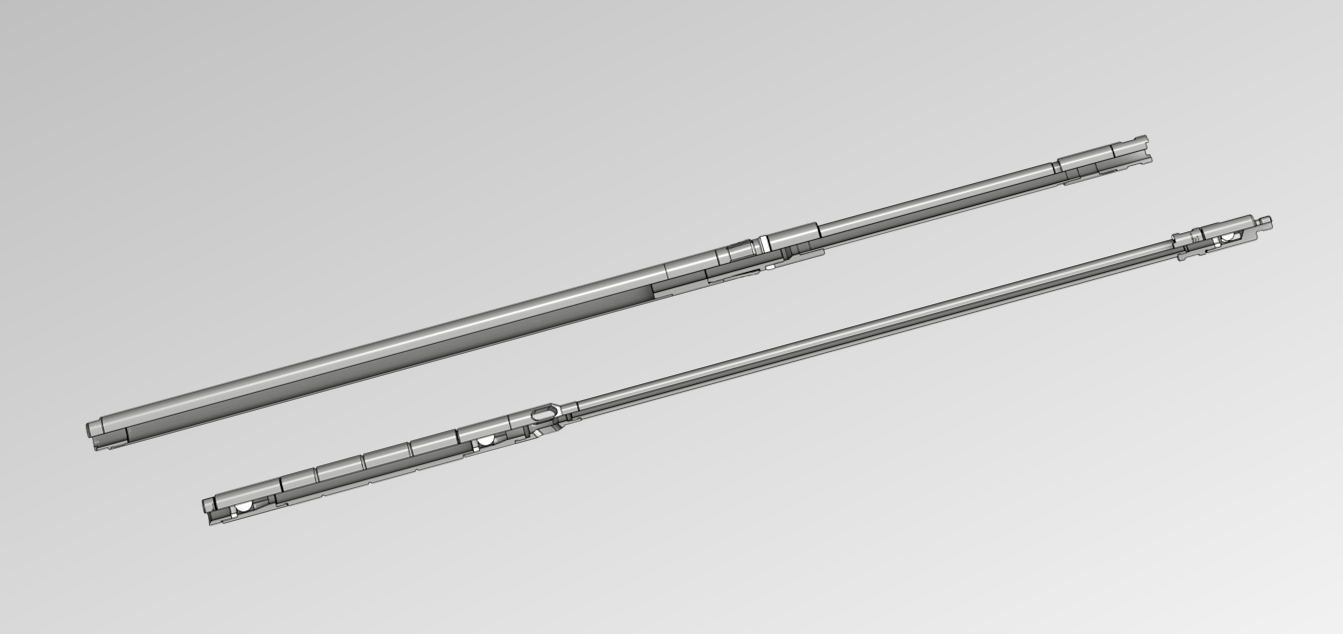

BARREL LENGTH PLUNGER PUMP

Black Gold Pump & Supply’s Barrel Length Plunger Pump is designed to improve pump efficiency and run times in the presence of sand, scale, and/or trash. The plunger assembly is designed to keep sand in suspension and to prevent sand from settling between the plunger and barrel. The plunger is wiped clean after every down stroke, mitigating the possibility of a stuck pump. Traveling and standing valve cages have a double valve to increase the potential run life of the pump.

DOWNLOAD SPEC SHEET

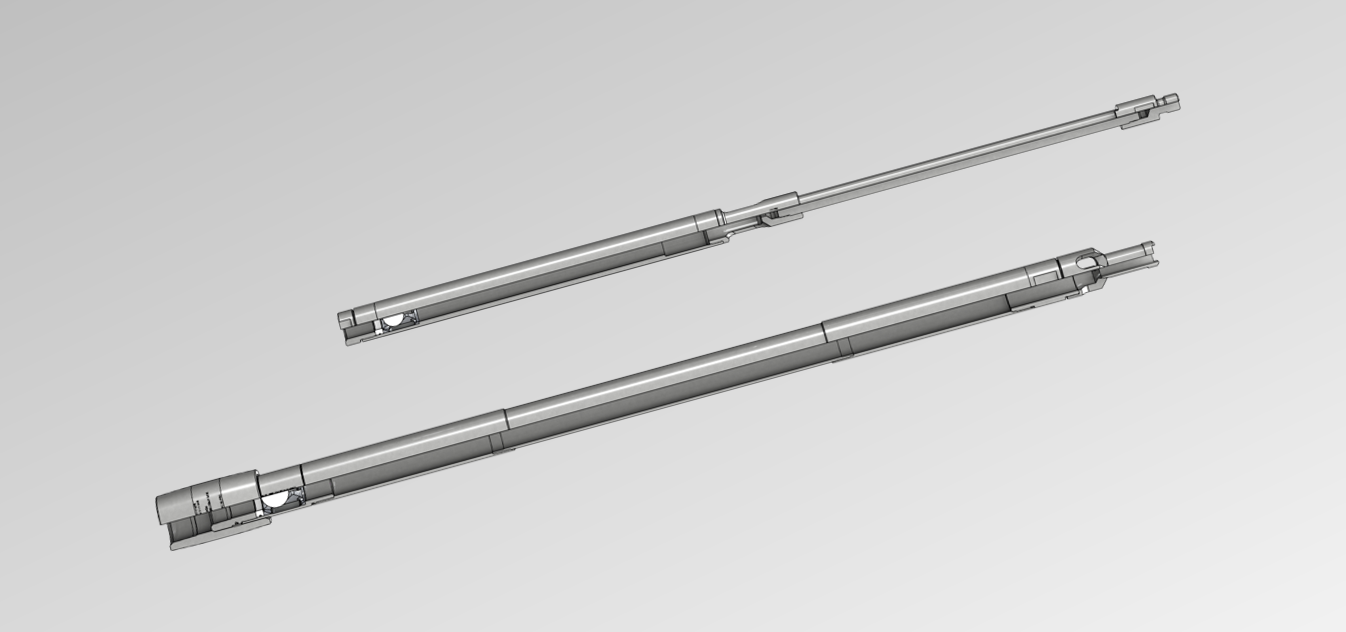

DOUBLE DISPLACEMENT PUMP

Black Gold Pump & Supply’s Double Displacement Pump is ideal for applications involving restricted pump bore size due to small casing diameters. The pump increases production without having to up size the pump bore or pumping unit. On the upstroke, fluid is produced like a normal tubing pump. On the down stroke, the added production is pushed into the production tubing. These pumps are all double valved for improved run life.

DOWNLOAD SPEC SHEET

NON-COMPRESSION PUMP

Black Gold Pump & Supply’s Non-Compression (NC) Pumps does not include a traditional standing valve. Instead, the pump design relies on the expansion and contraction of a vacuum zone between the upper plunger and lower barrel (the “production anulus”) to produce fluid. On the downstroke, the production anulus expands and generates a vacuum that unseats the traveling valve(s) below and allows fluid to fill the zone. On the upstroke, the same zone contracts and generates a pressure, therefore closing the traveling valve(s) below and unseat the top-open cage. This simultaneously forces the fluid out and upward into the tubing.

DOWNLOAD SPEC SHEET

CIRCLE-A PUMP

Black Gold Pump & Supply’s Circle-A Pump is mainly designed for heavy crude. The streamlined connections and minimum spacing between travelling and standing valves, create maximum flow while maintaining minimum turbulence of the fluid. The pump is held in place by a friction style hold down.

BLACK GOLD TUBING PUMP

Black Gold Pump & Supply’s Big Bore Tubing Pumps are double valved with nylon inserts to increase durability and run life of cages. Our plungers are grooved to allow for better lubrication. Our steel inserts are also available for high temperature applications.

DOWNLOAD SPEC SHEET

MENU

CONTACT US

Office, Pump Shop & Warehouse

Unit 4, 37-39 Devlan StreetMansfield 4122 QLD

Phone +61 7 3062 9475Fax +61 7 3252 7752

sales@vitalfluidsystems.com.au

STAY CONNECTED

Join our newsletter and find out more

Contact Us

Thank you for contacting us.

We will get back to you as soon as possible

We will get back to you as soon as possible

Oops, there was an error sending your message.

Please try again later

Please try again later