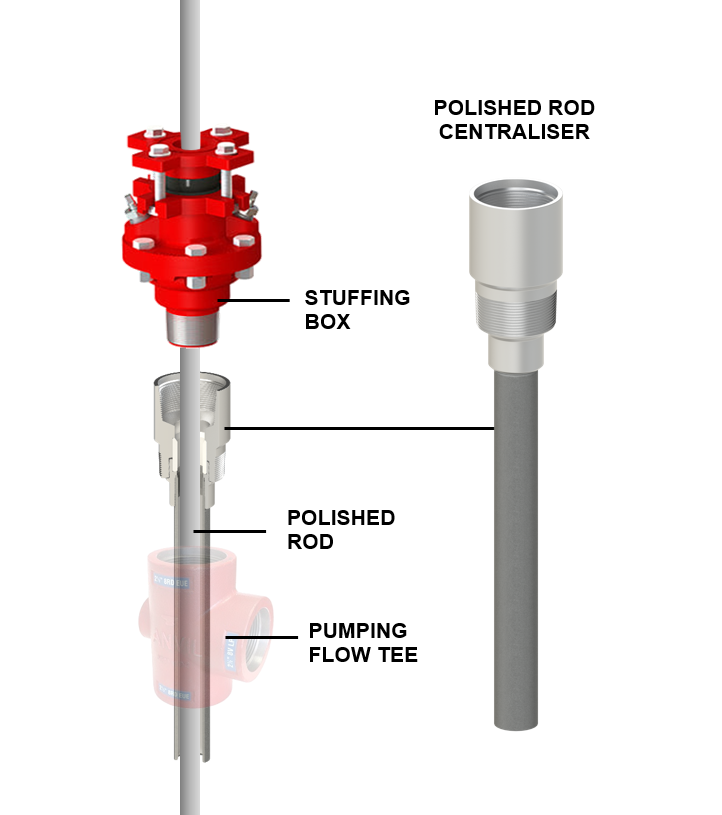

Polishes Rod Centraliser

- Prevents catastrophic blow out of stuffing box rubbers

- Creates up to a 50% decrease in differential pressure between the flow line and stuffing box (Black Gold tested)

- Centralizes polished rod in pumping tee

- Prevents uneven wear and extends life of stuffing box rubbers

- Prevents safety hazard, fines, loss of production, difficult clean-up and bad publicity

Download Brochure

Black Gold's Polished Rod Centralizer is a two-step pollution control product designed to increase the life of the stuffing box’s rubber and mitigate the chance of catastrophic leaks.

Installed between the stuffing box and production tee, the Polished Rod Centralizer centers the polished rod in a barrel. This eliminates any misalignment and significantly reduces wear on the stuffing box’s packing. In addition, the Polished Rod Centralizer greatly reduces the amount of pressure applied onto the stuffing box from the flow-line, and further minimizes leakage through the packing.

With this combination, the Polished Rod Centralizer has proven time and time again to be the solution that makes costly stuffing box failure a thing of the past.

Benefits of the Polished Rod Centraliser

Pollution Control

The Hydraulic Anchor is simple to install and simple to extract. The anchor comes with pre-made-up tubing couplings and the installtion process is just like adding a pup joint section.

Extraction is also straighrforward, once the anchor is disangaged (unsets), simply pull tubing to extract the anchor.

Centralising Polished Rod

The Hydraulic Anchor set and unsets via hydraulic differential pressure between the casing and the tubing. Once the pump seats, producers can either fill the tubing with fluid or start pumping fluid into the tubing. A low 10psi differential is all that is needed to set the anchor.

To unset the anchor, simple unseat the pump or or have a hole in tubing (via tubing drain), or reverse circulate the well.

Unlike conventional mechanical anchor, there is no surface manipulation needed.

Supplementary Seal

Unlike conventional mechanical anchor, there is no surface manipulation or pre-tensioning needed. The Hydraulic Anchor sets automatically via hydraulic differential pressure between the casing and tubing.

Producers typically save 45 minutes and up to a couple hours installing the Hydraulic Anchor instead of a conventional mechanical anchor.

Prevents Loss of Production

The Hydraulic Anchor has a strong holding power and is directly proportionate to the weight of the fluid column above the pump as the casing fluid level draws down. Which means the anchor holds stronger when its needed the most, resulting in higher pump efficiencies.

Specifications

| Polished Rod Size Range | 1.25", 1.5", 1.75" |

|---|---|

| Connections Top | 3" NPT, 2-7/8" 8RD EUE, 3-1/2" 8RD EUE |

| Connections Bottom | 3" NPT, 2-7/8" 8RD EUE, 3-1/2" 8RD EUE |

| Side Port Connection | 1/4" NPT connection for pressure transducer (available upon request) |

| Barrel Outer Diameters | 1.25” Centralizer – 1.625” OD / 1.50” Centralizer – 1.875” OD / 1.75” Centralizer – 2.125” OD |

| Maximum Pressure Rating | 3000 psi |

| Inserts | GF PTFE Insert prevents debris from entering barrel |

| Polished Rod Fit | -.005 to -.020 |

| Temperature Rating | 500°F |

| Barrel | Proprietary barrel design for corrosion and wear resistance |

MENU

CONTACT US

Office, Pump Shop & Warehouse

Unit 4, 37-39 Devlan StreetMansfield 4122 QLD

Phone +61 7 3062 9475Fax +61 7 3252 7752

sales@vitalfluidsystems.com.au

STAY CONNECTED

Join our newsletter and find out more

Contact Us

We will get back to you as soon as possible

Please try again later